- info@cecbearings.com

- +919924398116

Manufacturing Process

RAW MATERIAL & FORGING

The raw material used in the production of CEC bearings is SAE 52100, 100CRF, or 8620 steel, which meets international standards. This same steel is utilized for all bearing components, including races, cages, and rolling elements. The cages are made from CRC material and brass, in accordance with international standard specifications.

SPHEROIDIZE ANNEALING

Forged bearing rings undergo a spheroidizing annealing process, which enhances their ductility

and toughness by lowering hardness and strength, resulting in a well-defined microstructure.

CNC MACHINING

After the spheroidizing annealing process, the bearing rings are sent for CNC turning.

Each ring is then subjected to dimensional and visual inspection

HEAT TREATMENT

A crucial step in producing highly durable and long-lasting bearings is the heat treatment process. Our heat treatment includes hardening, super cooling, and tempering, which stabilize the ring structure and significantly extend the bearing's lifespan.

GRINDING

The grinding process consists of four stages:

1. Face Grinding: This stage uses a duplex machine, where components are checked for size variations, flatness, roughness, parallelism, and any signs of burning.

2. OD Grinding: Here, the material is examined for 2-point ovality, 3-point ovality, roundness, and roughness.

3. Track Grinding: In this stage, the track's size is inspected, along with curvatures, taper, eccentricity, roughness, 2-point ovality, and 3-point ovality.

4. ID Grinding: An electronic measuring system, known as the Marposs system, is used to control size variation. It ensures size precision by checking ovality, roughness, roundness, and other potential errors.

SUPER FINISHING

SAfter grinding, the bearing rings proceed to the super-finishing process. We utilize a globally certified CNC super finish machine

to achieve optimal roughness levels. We ensure that the roughness values for raceways and rollers are maintained below 0.16 microns.

INSPECTION

Before assembly, each bearing ring undergoes a thorough visual inspection. Our engineers carefully assess the size of all the rings in our state-of-the-art inspection room. Only rings that pass the stringent quality checks are moved forward for assembly. The instruments used in our lab include:

1. Zeiss Surfcom Touch 50

2. Rockwell Hardness Tester

3. Mitutoyo bore gauge

4. Mitutoyo height gauge

5. Zeiss Profilometer

and other advanced testing equipment.

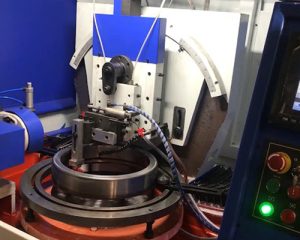

ASSEMBLY & PACKAGING

Our Assembly and Packing department is fully automated, with a daily packing capacity of up to 3,500 pieces. We prioritize export-oriented packaging to ensure that the products are securely packed and protected during transit, preventing any damage. Each component is carefully assembled and packaged using advanced techniques and high-quality materials to maintain the integrity and performance of the bearings throughout the shipping process. Our commitment to efficiency and quality ensures that every product reaches its destination in perfect condition.